Vacuum Trim Conveying

and Handling Systems for the

Paper Industry

103 Warner Drive, Long Sault,

Ontario, Canada, K0C 1P0

Tel: (613)932-3343

Fax:(613)937-0125

email: epm@hsp.ca

|

Vacuum Trim Conveying and Handling Systems for the Paper Industry |

103 Warner Drive, Long Sault, Ontario, Canada, K0C 1P0 Tel: (613)932-3343 Fax:(613)937-0125 email: epm@hsp.ca

|

| 1. Automatic trim chute air velocity control with the BERVAC Vacuum Trim Conveying System results in better roll end appearance and less noise at trim chutes |  |

| 2.

Energy

usage / cost with the BERVAC Vacuum Trim Handling System is less than half

of that for conventional trim handling systems

Example of yearly savings for a single winder:

Energy Savings = 80 kW (108 hp) |

|

| 3. Noise levels are low with the BERVAC Vacuum Trim Conveying System |

| 4. There is no need for pulper auxiliary equipment such as pulper air exhaust systems with the BERVAC Vacuum Trim Conveying System |

| 5. The BERVAC Vacuum Trim Conveying System eliminates air discharge problems at the pulper, since no large quantities of air are introduced into the pulper | ||

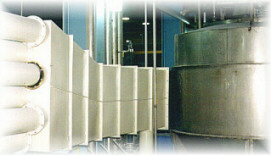

| Attempts to eliminate excess air prior to entering the pulper as required in conventional trim handling systems (photos) can be noisy, messy and require high maintenance |  |

|

|

||

| 6. The BERVAC Vacuum Trim Conveying System creates little or no dusting |

| 7. One BERVAC trim handling unit can handle the trim of several winders, rewinders, sheeters, rereelers, coaters, or any other equipment requiring trimming of a paper web or sheet |  |

|

|

| Photos show multiple ducts pneumatically conveying paper ribbon trim from various winders and sheeters (6 total) to a single BERVAC Separator |

| 8. The pneumatic handling of trim with the BERVAC Vacuum Trim Conveying System results in a cleaner work environment |

| 9. The BERVAC Vacuum Trim Handling System is a durable operation due to materials used and operating principle |

| 10. The paper trim ribbon can be conveyed distances of over 1000 feet with the BERVAC Vacuum Trim Handling System. Because there is no excess air which must be conveyed with the paper trim, air velocities are lower than with conventional systems and therefore smaller diameter ducting can be used. This allows longer duct distances and also allows the ducting to be configured and routed through difficult locations, eg.to avoid craneways. |  |

|

| 11. The cutting of side rolls or pony rolls, often friction elements in production, can be avoided with the BERVAC Vacuum Trim Conveying System |

| 12. The BERVAC Trim Handling System is easily connected to an existing pulper and allows the pulper to be used as a broke pulper as well |  |

| 1. The initial capital cost may be higher than a conventional system, if serving only one winder (but will be offset by energy savings) |  |

| 2. The option to divert broke to carts, floor or baler may add additional costs to the system. |