Vacuum Trim Conveying

and Handling Systems for the

Paper Industry

103 Warner Drive, Long Sault,

Ontario, Canada, K0C 1P0

Tel: (613)932-3343

Fax:(613)937-0125

email: epm@hsp.ca

|

Vacuum Trim Conveying and Handling Systems for the Paper Industry |

103 Warner Drive, Long Sault, Ontario, Canada, K0C 1P0 Tel: (613)932-3343 Fax:(613)937-0125 email: epm@hsp.ca

|

|

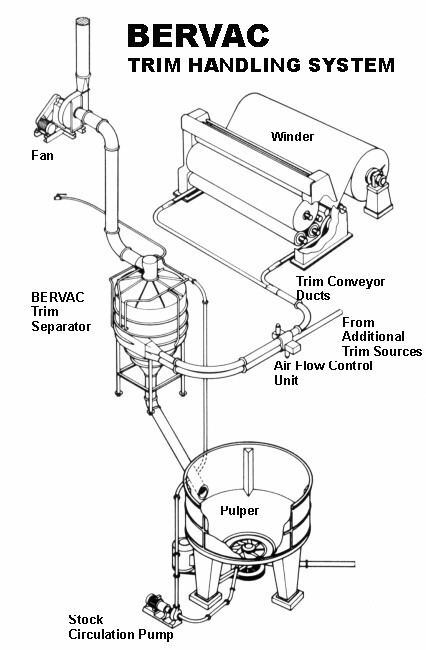

The

BERVAC Vacuum Trim Handling System operates on a principle where the paper

trim and broke are conveyed unbroken in ducts under low vacuum from a winder

or the like to the pulper.

The trim is separated from the air stream in a separator, using stock or white water.The separator is connected to the pulper by means of a discharge pipe. This connection to the pulper is made below the pulper stock level, which forms an air lock in the discharge pipe. No mechanical rotary feeder or similar trim feed equipment is required. The stock and white water used to flush the paper entering the separator down into the pulper is typically taken from the pulper recirculation and supply lines. The pressure differential required for the trim conveyance is produced with a standard centrifugal fan. As a result of this simple operating principle, the BERVAC trim handling system is very reliable in operation. Besides the standard design centrifugal exhaust fan, there are no wearing parts. A large number of winders may be served by a single BERVAC system. The BERVAC trim conveying system is suitable for the handling of practically all types of paper broke which allow pneumatic transport. See advantages of the Bervac Trim handling system. |

| BERVAC

Trim Handling System

Simple Flow Diagram

|