| The

BERVAC System

The

following is characteristic of the BERVAC trim handling system.

-

The trims

are conveyed unbroken under low vacuum from a winder, rewinder, sheeter,

rereeler, coater, etc. to the pulper

-

The trims

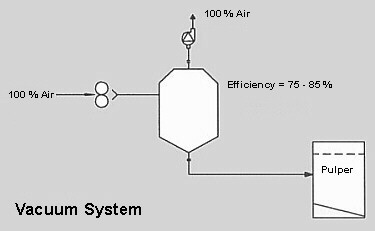

are separated from the air stream in a separator of special design, using

stock or white water. The BERVAC system is connected to the pulper

with an effluent pipe. The stock and white water supply is commonly

taken from the pulper circulation and supply lines

-

The pressure

differential required for trim conveyance is produced with a centrifugal

fan of high efficiency (in excess of 80%). As a result, the power

consumption of the BERVAC system is only a fraction of that of the conventional

trim conveying systems.

-

A pulper

exhaust system is not required.

-

Dimensioning

and detailing of a BERVAC system requires a thorough study of the winder,

and minor changes are occasionally required at the machine in order to

obtain a smooth removal of trims. These changes often make it possible

to increase the maximum trim width up to 250 mm.

-

The BERVAC

trim handling system is flexible and allows quite long conveying distances.

As a result of this, the nearest pulper does not necessarily have to be

used. It is often possible to reduce the running time of the winder

pulper, for example, with a timer, or in some cases, the pulper

may be shut down altogether.

-

Several

slitters, winders, rewinders, sheeters, coaters, rereelers,

etc. can be connected to the same BERVAC system, and their trims may be

treated and conveyed simultaneously. A prerequisite to this, however,

is that the system has been dimensioned with consideration to the number

of trims, and that the trim qualities allow them all to be conducted to

the same pulper. In a case where the same BERVAC system is to serve

several machines, it should be noted that , once dimensioned for all machines,

the BERVAC trim conveying system operates with all machines running just

as well as with only one machine running. This benefit allows the various

machines to be connected to the BERVAC system successively.

|

|